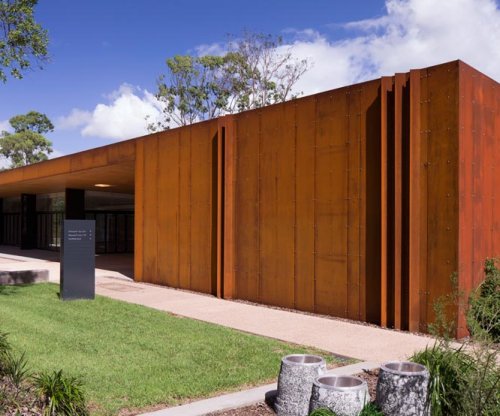

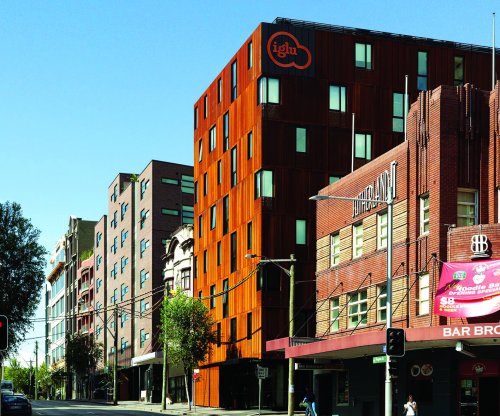

BlueScope manufactures a range of REDCOR® weathering steel for use in many applications from structural, such as bridges, to non-structural applications such as facades, screens, sculptures and noise-wall barriers.

REDCOR® steel develops a stable oxide layer on the surface of the steel known as the 'patina'. When detailed correctly and exposed to alternating wet and dry conditions, the colour of the patina changes organically over time, giving it a striking appearance.

Weathering steel allows you to bring the natural outback look and feel to the city and into your project. It evokes images that many readily associate with Australia such as the red Australian outback and celebrates the history of the Australian landscape.

There are two chemistry types of REDCOR® steel; product grades with an "A" suffix and product grades with a "B" suffix. Type "A" is manufactured with a higher phosphorous content to improve weathering-resistance for light-gauge plate and is typically used in facades and architectural applications. Type "B" material is made with lower phosphorous levels in order to improve the weldability of the steel for structural applications, such as bridges.

Further details regarding the formation of the patina and the correct use of REDCOR® steel are available in BlueScope's Technical Bulletin No.26. For other product and technical information, please refer to the relevant datasheet.

REDCOR® steel for structural applications

| Grade | Thickness (mm) | Width (mm) | Length (m) |

|---|---|---|---|

| AS/NZS 3678:2016 WR350B (L0, L20) | 10 - 80 | 1600 - 3000 | 4 - 18* |

*Any lengths >18m available by enquiry. Through Thickness Tensile tested grades (Z grades) are also available by enquiry.

REDCOR® steel for façade and other architectural applications

| Grade | Thickness (mm) | Width (mm) | Length (m) |

|---|---|---|---|

| AS/NZS 1595:1998 CW300A | 0.7 - 2 | 1155 - 1250 | - |

| AS/NZS 1594:2002 HW350A (coil plate) | 3 - 10 | 1155 - 1250 | 2.4 - 12 |

| AS/NZS 1594:2002 HW350A (coil) | 3 - 10 | 1155 - 1250 | - |

| AS/NZS 3678:2016 WR350A (L0, L20) | 8 - 12 | 1800 - 3000 | 4 - 18 |